Structural Shop Drawings Samples Comprise of a Set of Accurate and Robust Drawings That are Presented by The Manufacturer, Contractor, Fabricator, Sub-Contractor or Supplier.

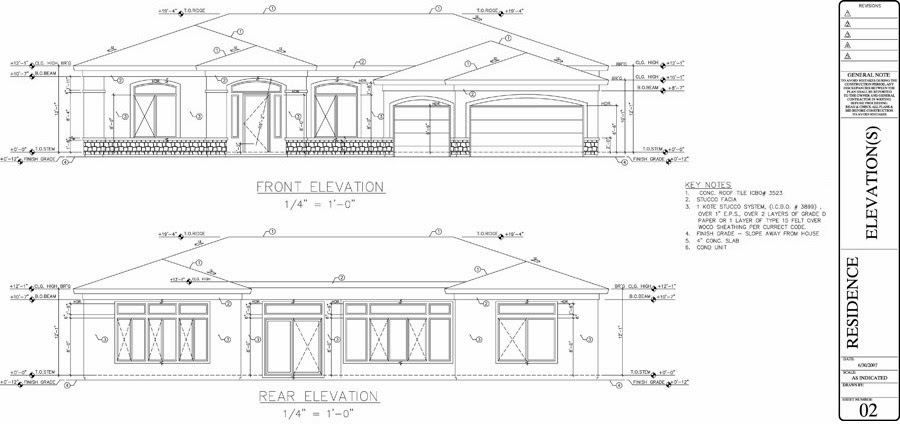

A requirement for pre-fabricated components, shop drawings including structural steel, elevators, appliances, pre-cast windows, millwork, air handling units, and cabinets. Besides structural shop drawings for MEP trade also include plumbing, piping, ductwork, electrical, and fire protection. It is typically a contractor’s or manufacturer’s drawn version of the information provided in different construction documents.

However, it presents more details than construction documents or BIM. Over the decades, structural shop drawings have become an integral part of a construction process, explaining details of installation or fabrication.

What are the Elements of Structural Shop Drawings?

Unlike common belief structural shop drawings samples are not presented by engineers and architects, and the details provided in the same also varied remarkably from that of an architect’s drawings. These are typically used for explaining installation and/or fabrication of items to the manufacturer’s or contractor’s installation and production team.

The key emphasis on such type of drawings is on the product or installation, and usually excludes the notations regarding other products and installations, unless it is absolutely necessary to integrate the product into the former. A shop drawing sample should include different elements that necessary details that distinguishes it from an architect’s drawing.

However, it presents more details than construction documents or BIM. Over the decades, structural shop drawings have become an integral part of a construction process, explaining details of installation or fabrication.

What are the Elements of Structural Shop Drawings?

Unlike common belief structural shop drawings samples are not presented by engineers and architects, and the details provided in the same also varied remarkably from that of an architect’s drawings. These are typically used for explaining installation and/or fabrication of items to the manufacturer’s or contractor’s installation and production team.

The key emphasis on such type of drawings is on the product or installation, and usually excludes the notations regarding other products and installations, unless it is absolutely necessary to integrate the product into the former. A shop drawing sample should include different elements that necessary details that distinguishes it from an architect’s drawing.

- Comparison information for engineers and architects – Structural shop drawings should incorporate valuable information for the engineer and architect to compare to their drawings and specifications. It should necessarily address appearance, perspective descriptions, and performance in construction and specification drawings. It should be comprehensive enough to let the engineer and architect review the fabricator’s or manufacturer’s version of the product, prior to final development. Specific references to construction documents, drawings, and specifications may also help the architect and engineer to review shop drawings. Finally, it should be clear and complete to help them approve the product.

- Information for fabricating the product – It is important for structural shop drawing samples to include manufacturing conventions, dimensions, and special instructions for fabrication. To put it simple, the drawings should be such so as to help the fabricator to understand what will be manufactured from the shop drawings only. Since the fabricator completely relies on shop drawings for all information, it should be accurate, specific, and precise. The samples should also include texture and color selection, and finishes.

- Computer-aided electrical, mechanical and plumbing design coordination – To address the issue of ineffectiveness related to 2D paper-based processes, more and more Architecture, Engineering and Construction (AEC) firms are using BIM in clash detection and coordination processes. Therefore, the shop drawings should present comprehensive details about mechanical, electrical, and plumbing designs, improving coordination among solid models and minimizing clashes.

- Installation or placement information – Some structural shop drawings samples also include data, instructions, and symbols related to installation and placement.

- Information of alterations or changes of construction documents – The shop drawings should also include information if there is any alteration or change from that of construction documents.

Nikunj Patel is an Engineering Consultant at Outsourcing Steel Detailing (OSD). The OSD is an India based Structural Steel Detailing Service Provider firm. Nikunj is expert in steel Detailing Design, Structural Designing and Auto CAD 3D Modeling.

12:27 PM

12:27 PM

Unknown

Unknown

Posted in

Posted in

excellent,thanks for ur information

ReplyDeleteCoordinated Shop Drawings

MEP Coordination